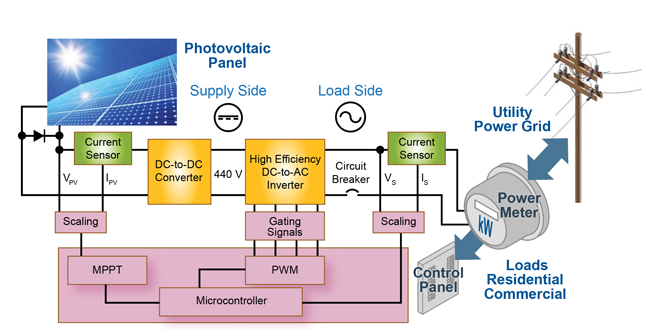

This picture shows a typical block diagram of a solar microinverter. The microinverter converts power from a single PV module and is usually designed for a maximum output power of 250W to 400W.

To maximize the performance of PV modules, the front end of a microinverter is a DC-DC section, and the digital controller performs maximum power point tracking (MPPT). The most common topology is a non-isolated DC-DC boost converter. For a single solar panel, the rail or the DC link is usually with 36V; in this voltage range, it is preferable to exploit standard metal-oxide-semiconductor field-effect transistors (MOSFETs) to carry out DC-DC conversion.

Given that size reduction is a priority (thus microinverters and power optimizers will be suitable for the back end of photovoltaic systems), solar inverter manufacturers are using gallium nitride (GaN) because of its higher frequency of switching, which helps to reduce the size of large magnetic components in applications of microinverters and solar optimizers.

A DC/AC inverter commonly employs H bridge topology circuit; for a microinverter, the voltage of the rail is approximately 400V. Currently, gate driver ICs can isolate the controller and the power switch with the help of a variety of isolation technology, and simultaneously drive the high-frequency switch. These requirements are driven by safety standards for signal isolation.

Higher efficiency means not only less energy waste, but also smaller radiators, less cooling requirements, and a more compact and cost-effective design. With the right high-voltage gate drivers, we can achieve higher efficiency while reducing system costs in the design of space-constrained microinverters or solar optimizers. Therefore, the overall cost of the construction, operation and maintenance of floating solar photovoltaic power plants can be reduced. Most important, with the improvement of the efficiency of floating solar inverters, there is no doubt that floating photovoltaics will have a more promising future and play a even bigger role in the industry. (Editor: Claire Jeawin)