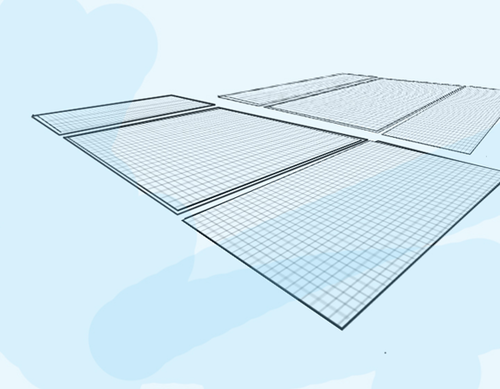

Compared with traditional photovoltaic power plants, floating solar photovoltaic farms mean that the power generation modules and the floating PV mounting system are installed on the surface of water bodies without occupying land. They have facilitated people's work and life. Plus, water bodies can cool PV modules and cables, which effectively improves the efficiency of power generation. In addition, floating solar PV power stations can reduce water evaporation and control algae growth, which benefits aquaculture and fishing.

In 2017, the world's first floating solar photovoltaic power station was built in Liulong Community, Tianji Township, Panji District, Huainan, Anhui, with a total area of 1,393 mu. Though being the world's first floating solar photovoltaic power station, there are two technical challenges waiting to be addressed.

The first one is the analog computation of the flow of wind waves. Since the power generation modules are installed on the surface of water, which differs from the stationary state of conventional solar photovoltaic power plants, it is necessary to conduct detailed analog computation of wind waves flow on every standard unit for power generation and provide the basis of design for anchoring systems and floating structures, to guarantee the safety of the floating panels. Specifically, the floating modules are self-adaptive to water-level anchoring system, and they employ ground anchor stakes equipped with sheathed steel wire ropes to connect the edge of the attached modules. There is an anchoring site every 6 meters or so, with cables retaining the flow to guarantee balanced force and safety, and to achieve the perfect integration of "stationarity" and "mobility".

The second challenge lies in the analysis of double glass, N battery and anti-PID non-glass modules and how to make the comparison more reliable. Also, it entails verifying the impact on power generation and the durability of floating materials. In this way, the floating power station will have an effective life span of 25 years and provide reliable data to support subsequent projects.

Floating PV power stations can be built on a variety of water bodies, whether natural lakes, artificial reservoirs, coal mining subsidence areas or sewage treatment plants, as long as there is enough water. They can not only turn "wastewater" into new energy carrier, but maximize the self-cleaning ability of floating PV, as they purify the water through the inhibition of water evaporation and algae growth. In addition, floating PV power stations can exploit the cooling effect of water to solve the cooling problem confronting road PV power stations. What's more, as built on open water and having enough light, the power generation efficiency of the stations expects to increase to about 5%.

After years of construction and development, the fact that land resources are strained and the expansion of urbanization have greatly limited the layout of road solar photovoltaics. Although it is viable to expands construction area through the reclamation of deserts and mountains, that just treats the symptoms but not the root cause. Today, floating photovoltaic technology is experienced profound development. As a new type of power station, floating solar photovoltaics do not need to scramble for valuable land with residents, instead they focus on the broader water areas, which complements road solar photovoltaics and contributes to diversified development and win-win scenario. (Editor: Claire Jeawin)